Famous for its estery development and some spicy notes.

Specialty yeast selected for its estery somewhat peppery and spicy flavor development (POF+), producing clovelike aroma. Yeast with a medium sedimentation: forms no clumps but a powdery haze when resuspended in the beer.

Ingredients

Yeast (Saccharomyces cerevisiae), emulsifier E491.

Dosage/Temperature

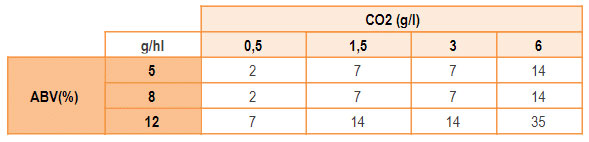

50 to 80 g/hl at ideally 15-20°C (59-68°F).

Usage

Lesaffre know-how and continuous yeast production process improvement generates an exceptional quality of dry yeasts able to resist to a very wide range of uses, incl. cold or no rehydration conditions, without affecting their viability, kinetic and/or analytical profile. Brewers can choose usage conditions that fit the best their needs, i.e.:

① Direct pitching:

Pitch the yeast directly in the fermentation vessel on the surface of the wort at or above the fermentation temperature. Progressively sprinkle the dry yeast into the wort ensuring the yeast covers all the surface of wort available to avoid clumps. Ideally, the yeast will be added during the first part of the filling of the vessel; in which case hydration can be done at wort temperature higher than fermentation temperature, the fermenter being then filled with wort at lower temperature to bring the entire wort temperature at fermentation temperature.

② With prior rehydration:

Alternatively, sprinkle the yeast in minimum 10 times its weight of sterile water or boiled and hopped wort at 25 to 29°C (77°F to 84°F). Leave to rest 15 to 30 minutes, gently stir and pitch the resultant cream into the fermentation vessel.

| Total esters | Total superior alcohols | Apparent attenuation | Sedimentation | Alc. Tolerance (ABV) |

| High | Medium | 70% | Medium | 9-11% |

Fermentis dry brewing yeasts are well known for their ability to produce a large variety of beer styles. In order to compare our strains, we ran fermentation trials in laboratory conditions with a standard wort for all the strains and standard temperature conditions (SafLager: 12°C for 48h then 14°C / SafAle: 20°C). We focused on the following parameters: Alcohol production, residual sugars, flocculation and fermentation kinetic. Given the impact of yeast of the quality of the final beer it is recommended to respect the recommended fermentation instructions. We strongly advise users to make fermentation trials before any commercial usage of our products.